Overview

Quasi-S Engineering division consists of teams of specialists with vast experiences in the following major roles:

- Equipment installation, calibration, buy-off, evaluation, trouble shooting and preventive maintenance.

- Site measurement includes EMF, noise and vibration elimination.

- Vacuum Pump preventive and corrective maintenance, UPS installation and battery replacement and many more.

- Provide customized solution and tailor to the need in overcoming customers’ problems. Unlike any common engineering services available in the market, we specifically focus only on projects that sync with our expertise.

- 3D CAD design and drafting services (using latest Autodesk Inventor) to clients

– For complicated and sophisticated mechanical structures that require in-depth visualisation.

– For “Reverse Engineering”, mainly for parts that are EOL and no longer available.

Engineering Examples

Below are examples of Engineering projects and several drafting assignments we have undertaken. The list is exhaustive somewhat, but due to customer proprietary requirement the examples shown is limited.

01

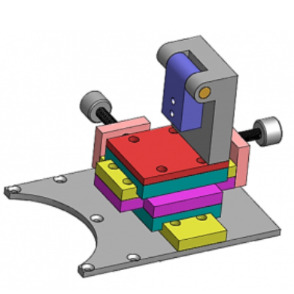

3D AutoDesk Designs & Draftings Services

With years of engineering project experiences, our team of mechanical engineering designers have undertaken and worked with multiple industry partners. From machine components to nano instrument stages to jigs and fixtures, we are well equipped to provide comprehensive and timely solution and services.

Below are some examples:

PLD Chamber

Microscope X-Y-Z Stage

Vacuum Chamber Camera Assembly

02

Pump Overhaul Services

Quasi-S provides overhaul and repair services on various vacuum pumps such as turbo pumps, dry/scroll pumps, rotary pumps, etc. And we are specialized in Agilent, Edwards and Ulvac Pumps.

Our engineers are trained in various vacuum systems to provide comprehensive service and repair for our customers. We ensure complete service kit of gaskets, filters, oil replacement up to vacuum level testing to performed at every request. During final test, we will monitor total pressure, temperature, vibration and noise level of the pumps. Upon request, we can provide our customers with pump down graph.

TRP Series pump, Vacuum Pump TRP-12

03

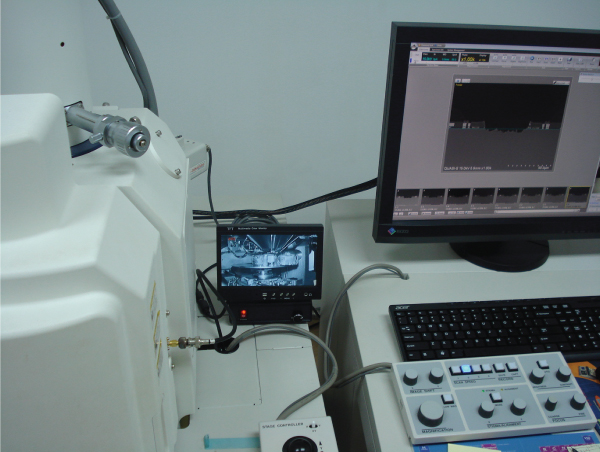

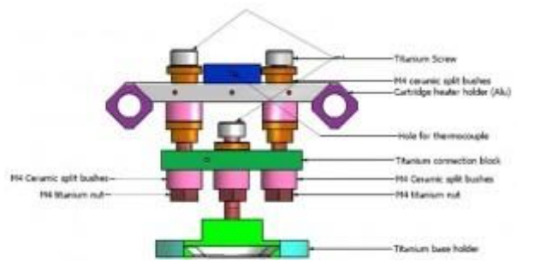

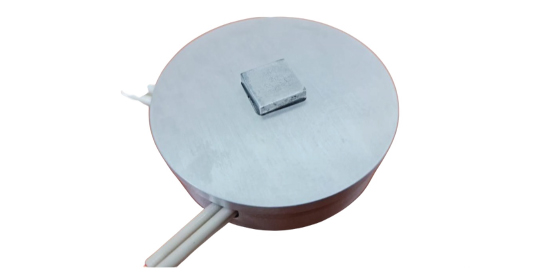

In-situ Heater Stage For Scanned Electron Microscope (SEM)

Quasi-S in-situ heater stage is a high temperature heating module for material handling experiments in combination with microscopic observation. SEM sample holder with in-situ heater capabilities for SE imaging. It is designed to allow universal handling of various specimens. The heater can be mounted on the stage of a SEM like a regular sample. A K-type thermocouple allows the measurement of the temperature at the specimens. The temperature can be observed and controlled by PID temperature controller.

This in-situ heater stage provides sample heating up to 300⁰C and the system consists of:

- Heater stage with K type thermocouple, cartridge heater and dovetail base holder

- Flange with feed through

- Temperature controller module

04

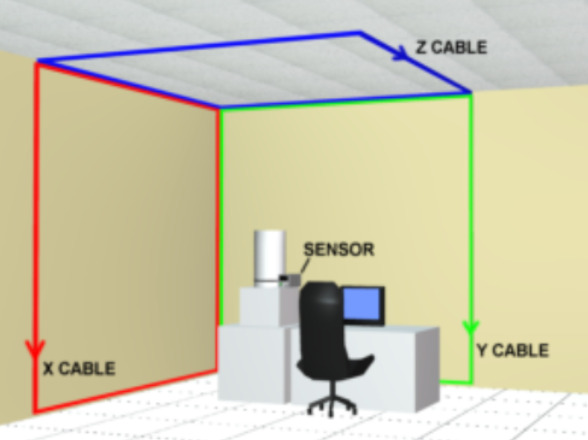

Site Measurement (Electromagnetic, Vibration & Acoustics)

Quasi-S offers site measurement services using high precision Analysis System. The standard measurement provides data about a proposed site for equipment installation such as a Scanning Electron Microscope and other equipment which is sensitive to environmental conditions. We measure magnetic fields and floor vibrations in X, Y and Z directions and acoustic levels in units appropriate for direct comparison with the environmental specifications of the equipment to be installed.

The latest equipment on the market requires low levels of magnetic field and magnetic field gradients and we can uniquely able to offer surveys measuring the field simultaneously to obtain this gradient information for both DC and AC fields. We are also able to provide technical solutions and customized designs to cancel or minimize environmental interference affecting your work area and equipment.

05

Noise Reduction Enclosure

Another project successfully undertaken by Quasi-S. This simple, cost effective enclosure not only helps our client to reduce health hazard due to noise generated by over 40 pumps, but the external casing creates neatness in the factory 5S initiative.

With the enclosure Temperature peaked at 49°C and remained constant after 8hrs of continuous operation.